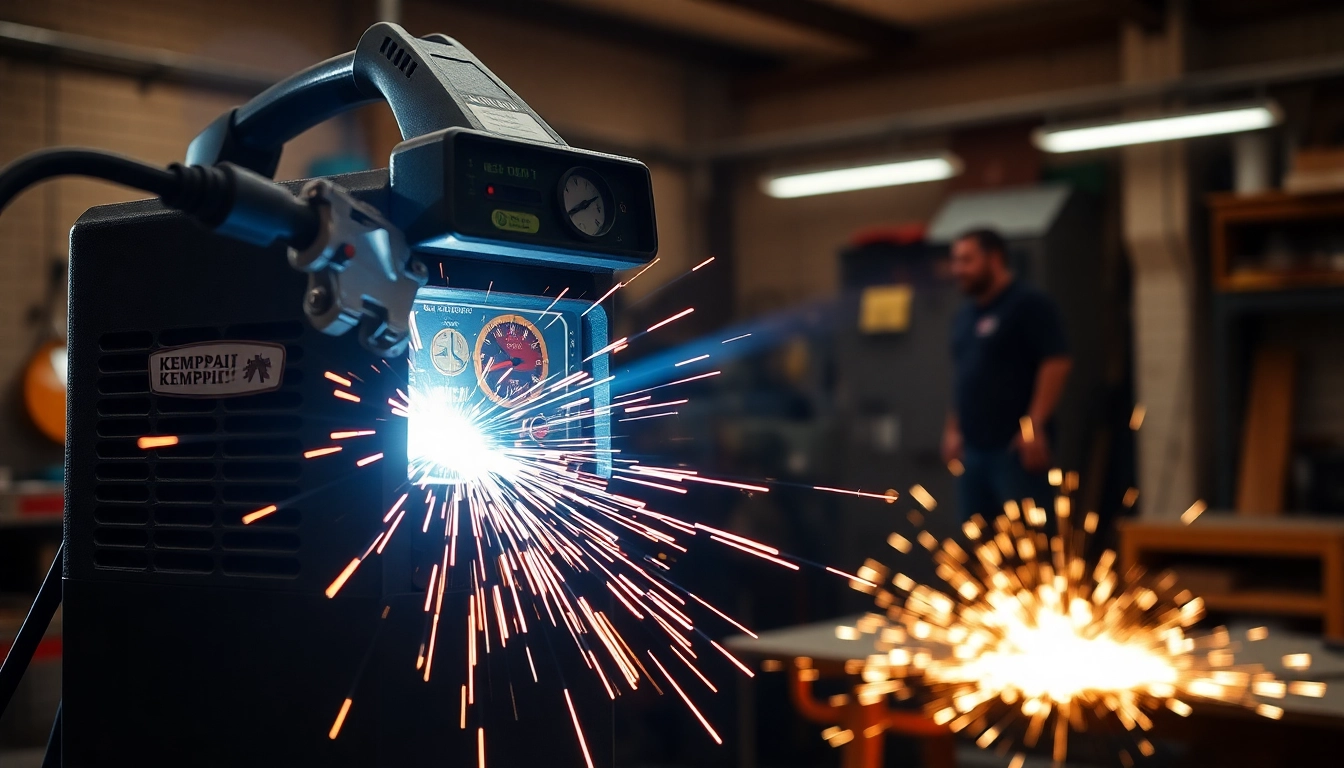

Introduction to Kemppi Welders

When it comes to high-quality welding solutions, Kemppi welders have established themselves as a premier choice for professionals across various industries. Renowned for their innovation and reliability, these equipment pieces are more than just tools—they represent the cutting-edge of welding technology. With a commitment to efficiency and precision, kemppi welders cater to a diverse range of applications, making them a pivotal asset in any welder’s toolkit.

What Makes Kemppi Welders Stand Out?

Kemppi welders stand out due to their exceptional build quality, innovative technologies, and user-friendly features. They are designed to cater to the needs of diverse welding applications, from light fabrication to heavy industrial work. Key features include:

- Advanced Arc Control: Kemppi’s proprietary arc control technology ensures a stable arc, which translates to consistent weld quality.

- Durability: The robust design minimizes wear and tear, allowing for long-term use without compromising performance.

- Intuitive Interfaces: User-friendly displays and control systems allow for easy adjustments and settings, reducing learning curves for new users.

Moreover, these welders are often equipped with features such as energy-saving modes and advanced monitoring systems, which not only enhance performance but also minimize operational costs.

History and Evolution of Kemppi Welding Technology

Kemppi has a rich history in the welding sector, having been established in 1949 in Finland. The company has continually evolved to meet the changing demands of the industry, investing heavily in research and development to enhance their product offerings. This commitment to innovation is evident in their development of MIG welding technology in the 1970s, which revolutionized the field.

Over the years, Kemppi has expanded its global presence and product lines, adapting to various markets and customer needs. Today, it stands as a leader not only in arc welding technology but also in software solutions for welding management and quality control.

Key Applications for Kemppi Welders

The versatility of Kemppi welders allows them to be used across a myriad of industries. Key applications include:

- Aerospace: Precision welds are essential for aircraft manufacturing, making Kemppi’s TIG and MIG welders ideal for this sector.

- Automotive: The automotive industry benefits from Kemppi welders in both assembly lines and specialized restorations.

- Construction: From heavy machinery to structural steelwork, Kemppi welders offer the durability and performance required in construction.

- Shipbuilding: Due to their robust performance, these welders are well-suited for the demanding conditions of shipbuilding.

Different Types of Kemppi Welders

MIG Welders: Versatility and Efficiency

MIG welding is one of the most commonly used welding processes worldwide, and Kemppi has crafted a range of MIG welders that highlight both versatility and efficiency. These machines are ideal for both beginners and seasoned professionals due to their ease of use and adaptability across various materials, including steel, aluminum, and stainless steel.

One standout model is the Kemppi MinarcMig series, known for its lightweight design and advanced features such as synergic control and Smart Cool technology. These features help in achieving consistent welds while optimizing the welding parameters automatically.

TIG Welders: Precision at Its Best

TIG welding is celebrated for its capability to create precise and high-quality welds, especially on thin materials. Kemppi’s TIG welders, such as the MinarcTig series, provide exceptional control over the weld pool and are equipped with technology that allows for seamless operation across a variety of metals.

The MinarcTig 200, for instance, boasts a highly-efficient inverter design that reduces energy consumption while providing stable arc characteristics, making it a prime choice for professionals seeking accuracy and reliability in their welding projects.

Multi-Process Welders: Mix and Match Techniques

For those who require flexibility in their operations, Kemppi offers multi-process welders like the MasterTig and MasterMig series, which can handle MIG, TIG, and even Stick welding processes. These welders are particularly useful in settings where different welding techniques are frequently needed, such as in repair shops or fabrication units.

The multi-process capability not only provides versatility but also simplifies training for operators as they can become proficient in different welding techniques using a single machine.

Choosing the Right Kemppi Welder for Your Needs

Factors to Consider Before Buying a Kemppi Welder

When selecting the right Kemppi welder, various factors must be taken into account:

- Type of Welding: Determine whether you need MIG, TIG, or a multi-process welder based on your projects.

- Material Type: Consider the materials you will primarily work with, as some welders perform better with specific metals.

- Power Supply: Match the welder’s power supply requirements with your operating environment, whether it’s standard single-phase or three-phase current.

- Portability: For those working on-site, a lightweight and portable welder may be necessary.

- Budget: Establish a realistic budget that factors in not just the welder but also additional costs like gas, consumables, and maintenance.

Comparative Analysis of Popular Kemppi Models

To assist in choosing, here is a comparative overview of some popular Kemppi models:

| Model | Type | Key Features | Best For |

|---|---|---|---|

| MinarcMig 200 | MIG | Lightweight, easy to use, advanced synergic settings | Steel and stainless steel fabrication |

| MasterTig 200 | TIG | Compact design, high performance, best for thin materials | Aerospace and automotive industries |

| MasterMig 300 | Multi-process | High power capacity, excellent arc performance | Heavy fabrication and construction |

Real-World Use Cases and Success Stories

Several users have successfully implemented Kemppi welders in their operations. For example, a prominent automotive manufacturer implemented the MasterTig series for its precision welding needs, leading to a 20% reduction in welding time and enhanced weld quality. Similarly, a shipbuilding yard noted a significant increase in productivity when using the MinarcMig series, allowing them to complete projects ahead of schedule due to the welder’s efficiency and reliability.

Maintenance and Safety Tips for Kemppi Welders

Regular Maintenance Practices for Longevity

Proper maintenance of your Kemppi welder is essential to ensure its longevity and performance. Consider the following practices:

- Cleaning: Regularly clean the welder of any debris and contamination to prevent malfunction.

- Inspecting Cables and Connectors: Check the power leads and welding cables for any signs of wear and tear. Replace any damaged components immediately to prevent accidents.

- Cooling System Maintenance: Ensure that the cooling system is functioning adequately; most Kemppi welders have built-in cooling options that require periodic checks.

- Routine Calibration: Perform calibration to maintain accuracy in performance and to achieve consistent weld quality.

Safety Measures While Using Kemppi Welders

Safety is paramount in welding. Adhere to the following safety measures:

- Personal Protection Equipment (PPE): Always wear appropriate PPE, including gloves, aprons, and helmets with the correct filter shade.

- Ventilation: Use welders in well-ventilated areas to avoid harmful fumes and gases.

- Emergency Procedures: Familiarize yourself and your team with emergency procedures, ensuring extinguishers and first aid kits are readily available.

Common Troubleshooting Tips

Even the best equipment can face issues. Here are common troubleshooting tips for Kemppi welders:

- Welding Arc Won’t Start: Check the power supply, ensure connections are tight, and verify that settings are correctly adjusted.

- Inconsistent Weld Quality: This can often be traced back to a dirty workpiece or incorrect settings. Ensure proper preparation of materials and review the machine’s settings.

- Overheating: Ensure that cooling systems are working and that you’re not overloading the machine; always use according to the specifications.

Where to Buy Kemppi Welders

Top Retailers and Online Stores for Kemppi Welders

Finding authentic Kemppi welders is vital for ensuring quality and reliability. Some of the top retailers and online platforms to consider include:

- Authorized Distributors: Seek out authorized distributors like Alpha Weld and Rapid Welding who provide the latest models and genuine products.

- Online Marketplaces: Websites such as eBay and Amazon often have various Kemppi welding products but ensure the seller is reputable.

How to Compare Prices and Find Discounts

When shopping for Kemppi welders, it is essential to compare prices across different platforms:

- Price Comparison Tools: Use online comparison websites to gauge market prices before making a purchase.

- Seasonal Sales: Keep an eye out for seasonal discounts and promotions, as many retailers offer deals during holidays.

Customer Reviews and Recommendations

Before making a final decision, check customer reviews on platforms such as Reddit and specialized welding forums. Users often share valuable insights into specific models and their performance over time. Positive feedback on longevity and performance, coupled with a few mixed reviews regarding the learning curve, can help prospective buyers make well-informed decisions.